LPG Transformer

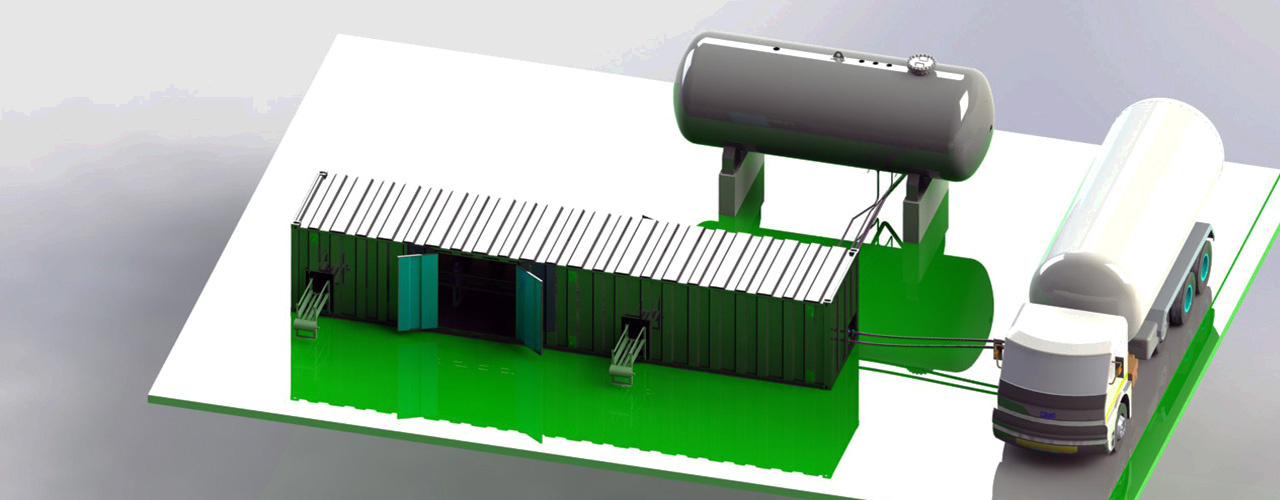

Modular Solution for LPG business:

A complete cylinder filling plant inside container. Drop the box, connect to the storage tank, connect to electric main and switch on.

Ideal for developing new companies, or expanding business to new areas.

Effective solution during maintenance and shut-down periods.

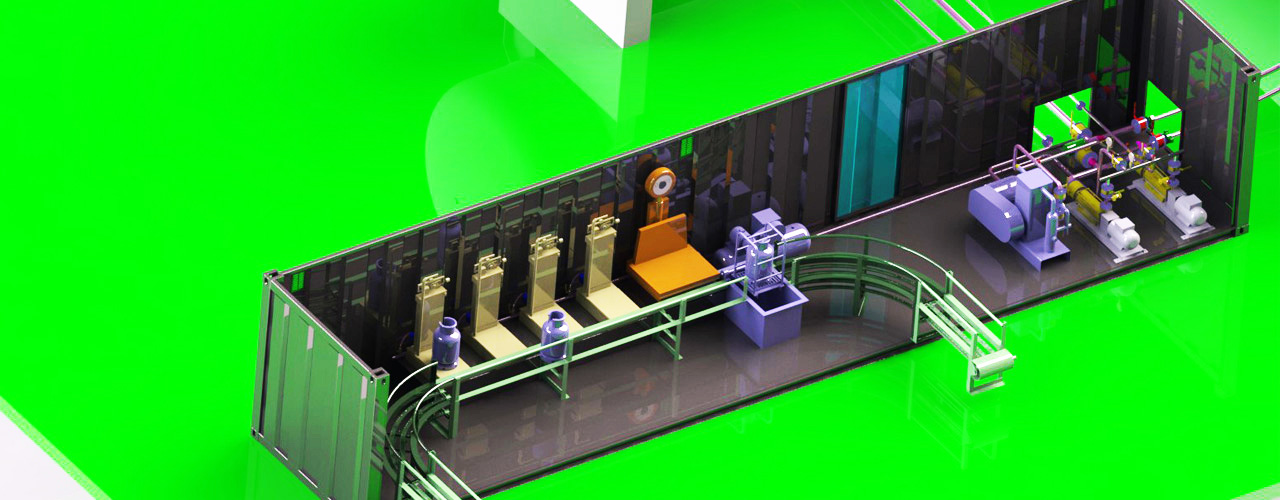

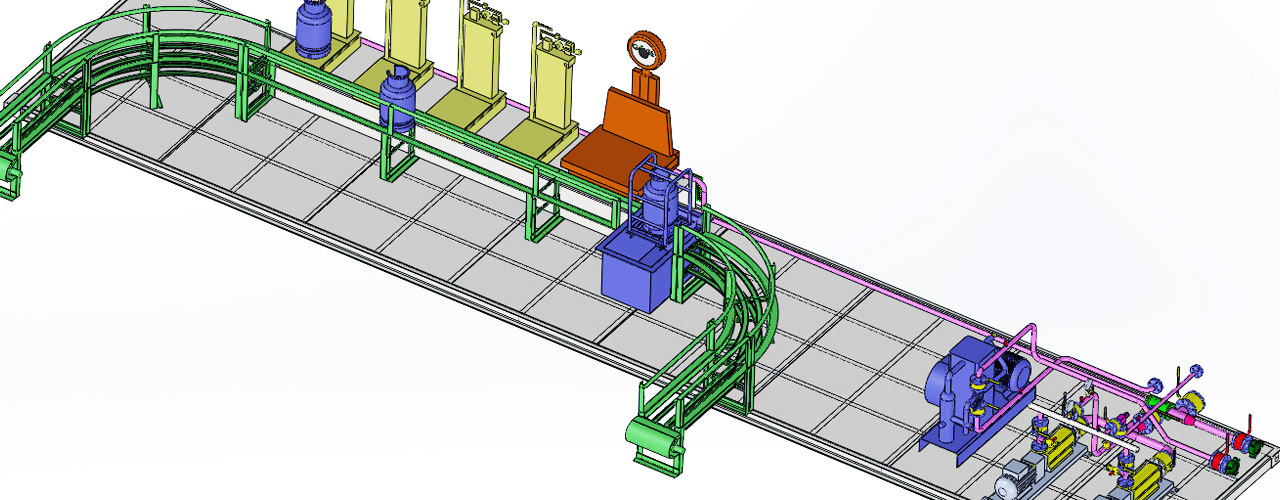

Includes all necessary machinery, conveyors, piping and wiring.

Can be disassembled and transported.

Fits inside a 40’ container.

The package can be connected to any size of new or existing LPG storage tank. For new tank orders, piping from tank to container will be supplied in modular form.

| Capacities | |

| Cylinder filling (*) | 200 to 300 cylinders/hour |

| LPG pump (each) | 3 - 4.5 m³/h 5,5 - 8,4 bar(diff) |

| LPG pumps (total) | 6 - 9 m³/h 5,5 - 8,4 bar(diff) |

| Standard Package | |||

| 1 | Container | 1 pc. | 11736 x 2240 x 2200 mm |

| 2 | LPG cylinder filling scale (*) | 4 pcs. | 200 cylinder/hr |

| 3 | Chain conveyor, U shape | 1 set | 3.6 kW |

| 4 | Check scale, mechanical, high precision | 1 pc. | 150 kg/50 g. |

| 5 | Leak Detection Pool | 1 pc. | 1 cylinder, pneumatic lift |

| 6 | LPG pump | 2 pcs. | 4,5 m³/h @ 5,5 bar(diff) 3 m³/h @ 8,4 bar(diff) |

| 7 | Air compressor | 1 pc. | 2 Nm³/hr |

| 8 | LPG Hose, with 3 ¼” ACME connectors | 2 pcs. | 2” x 6 m |

| 9 | Gas detector | 2 pcs. | Ex-proof |

| 10 | Light fixture | 6 pcs. | 60 W / 9-11 W |

| 11 | Electric Panel | 1 set | 230 / 400 V 50 Hz 12 kW |

| Fire extinguisher | 2 pcs. | 12 kg. | |

| 12 | LPG piping, compressed air piping, electric installation | 1 set | |

(*) Standard package contains four filling scales for filling domestic cylinders with 10 – 13 kg gas capacity. The given capacity is for standard model. Maximum 6 filling scales can fit inside the container, which enables 300 cyl/hour.

For filling camping or industrial cylinders additional filling scales will be necessary. In this case, filling capacity will be proportional to the gas weight.

Options

Additional filling scales or scales for different type/size of cylinders.

Electronic filling scales.

Electronic leak detector.

Electronic check scale.

Cylinder decanting machine.

LPG compressor.

Voltage/frequency other than 230-400 volt 50 Hz.

Protective cabinet with lock.

Heat insulated roof.

Transformer is engineered and constructed according to NFPA 58.

All electric equipment of Transformer has ATEX certification.

Equipment and machinery conforms the EU standards and has CE markings.

Performance of the machinery and equipment of Transformer has proven by LPG industry.